Urethane methacrylate resin for carbon composites

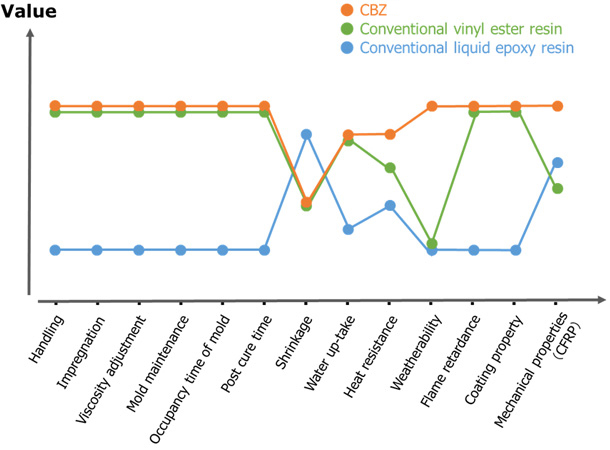

Japan U-pica has developed thermosetting resins that are similar in handling to conventional unsaturated polyesters and vinyl ester resins and can be applied to various molding methods (liquid resins and prepreg resins).

Developed resins have excellent curing properties and physical properties, contributing totally to lower costs.

-

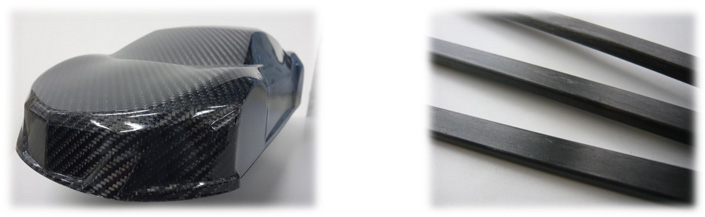

The list of CBZ resins

-

The features & benefitsFeatures

- Excellent bonding to carbon fiber sized for epoxy.

(Carbon fiber sized for VE resins as well.) - Good paintability.

- CBZ can be cured at wide range of temperature.

Benefits- The lightweight CF-composites can be obtained.

- CBZ can be applied to various molding methods.

- High cycle.

- CBZ can be applied to mold large-sized products.

- Excellent bonding to carbon fiber sized for epoxy.

-

The application of CBZ

-

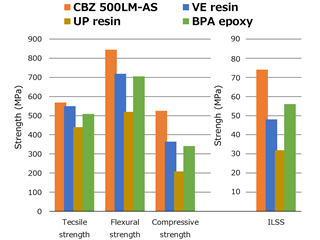

The mechanical properties■ High strength grade CBZ 500

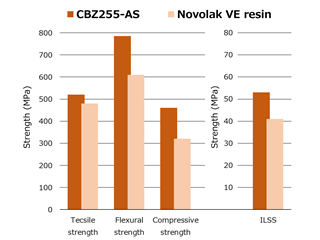

■ Heat resistance grade CBZ 255

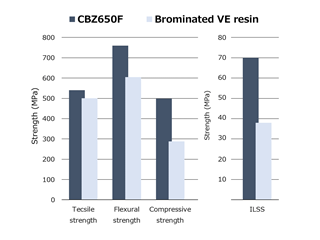

■ Heat resistance grade CBZ 255 ■ Fire retardant grade CBZ 650

■ Fire retardant grade CBZ 650 *VE = vinyl ester resin, UP = unsaturated polyester resin

*VE = vinyl ester resin, UP = unsaturated polyester resin[Conditions for preparation of CF laminates] Fiber :TORAYCA CO6343 (T300 plain woven fabric) Molding :Hand lay-up (VF:39~41%) Formulation :CBZ :resin / PR-CBZ01 /328E = 100 / 0.5 / 1.0 VE、UP :resin / 6%Co / PERMEC N =100 / 0.5 / 1 epoxy :resin / amine = 100 / 30 Curing :CBZ, VE, UP :23℃/3h + 60℃/2h + 80℃/2h + 120℃/2h :epoxy :23℃/5h + 130℃/2h + 150℃/2h -

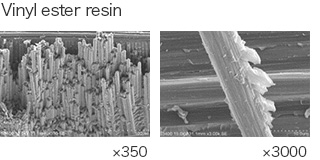

Why use CBZ?① High adhesion with carbon fiberHigh adhesionFracture surface after tensile test (SEM image)

CBZ resins have excellent mechanical properties,

CBZ resins have excellent mechanical properties,

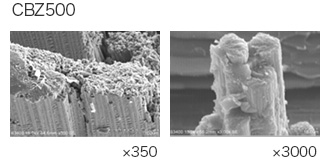

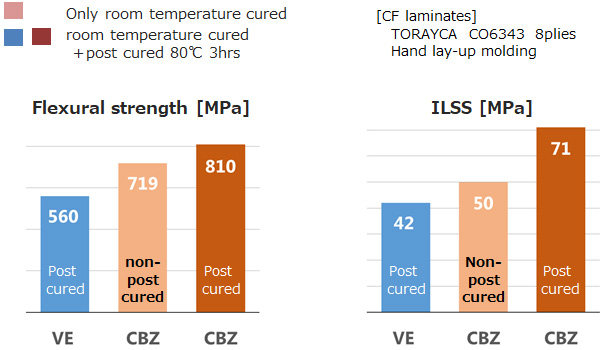

because of high adhesion with carbon fibers.Mechanical propertiesRoom temperature cured CBZ, even non-post cured, can provide better mechanical properties than 3hrs post cured standard vinyl ester resin. Contribution to weight reduction and cost reductionBecause of the superior physical properties of CFRP with CBZ, it can be designed to be thin in relation to the required load capacity.

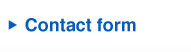

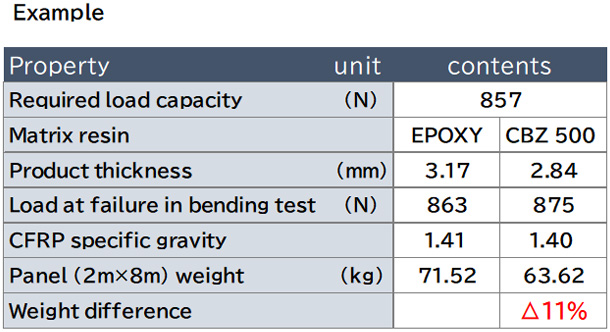

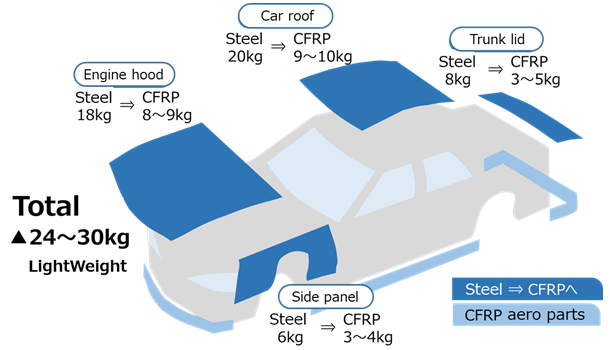

Contribution to weight reduction and cost reductionBecause of the superior physical properties of CFRP with CBZ, it can be designed to be thin in relation to the required load capacity. The reduction of weight of the car bodyThe sports car

The reduction of weight of the car bodyThe sports car

Molding:VaRTM, Resin:CBZ500LM-AS

-

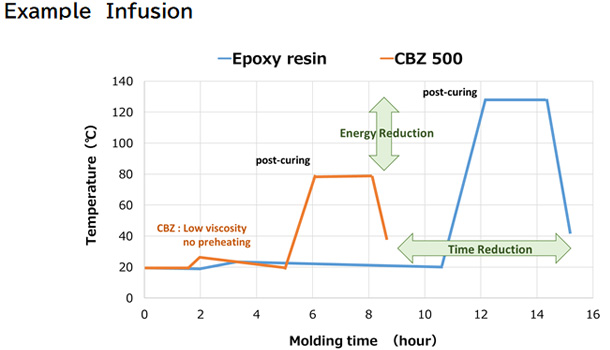

Why use CBZ?② High cycle & high productivityenergy efficiency & conservation

- No preheating of resin or mold.

- Short curing time.

- Reduction of energy consumption by shortening the molding cycle.

- Low temperature extends mold life.

-

The values of CBZ

-

Others

- We are currently developing intermediate materials

(Prepreg, SMC, and Tow-prepreg) for CBZ. - Please contact us if you are interested in intermediate substrates featuring "High cycle", "High mechanical properties","Room temperature storage".

- We are currently developing intermediate materials