Products

Compound for press-molding and injection-molding

U-Pica SMC(Thermosetting Sheet Molding Compound)

Please use the contact form

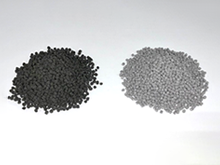

Vyloglass

Vyloglass is a thermosetting dry-type molding compound made up of crystalline unsaturated polyester resin.

It has outstanding heat resistance, flame retardance and electrical properties. It outperforms BMC in terms of handling

efficiency, moldability, and storage stability. Also it is available in various grades with different features for applications which require high reliability such as electric equipment, electronic devices, electric components for automobiles, and heat resistant parts. Moreover it does not melt even at high temperatures, hence improves the safety of products to a large extent.

-

Heat Resistance Relative Thermal Index 180 ℃ Heat Distortion Temperature 250 ℃ Flame Retardance Flammability UL94 V-0 Glow-wire Test

Halogen and Antimony-Free960 ℃ Electrical Properties Arc Resistance 195 sec. Tracking Index 900 V Moldability Pellet for good handling and measurability Can be molded by injection, transfer, or press molding 6 months guarantee for temperature below 30 ℃

-

Grade

Features VG-2200 VG-7100 VG-7150 Heat Resistant ○ ○ Flame Retardant ○ ○ Insulation Resistant ○ ○ ○ High Strength High Thermal Conductivity ○ Biomass Resource Used Excellent Light Reflectance Production Scale* C C C * C Commercial scale, L Laboratory scale -

Technical data

Grade VG-2200 VG-7100 VG-7150 Feature General Heat resistance Heat dissiption Thermal properties Heat deflection JIS K6911 ℃ 290 280 ≧250 Flexural strength, at 200℃ JIS K6911 MPa 30-40 30-40 - Upper limit of use temperature PSE ℃ 180 185 - Relative thermal index UL 746B ℃ - 180℃(3mm) 130℃(0.75mm) Thermal conductivity Laser flash method W/m・K 1.51 1.60 1.65 Electrical properties Dielectric strength JIS K6911 kV/mm ≧12 ≧15 ≧15 Insulation resistance, nomal JIS K6911 Ω ≧1014 ≧1014 ≧1013 after boiling JIS K6911 Ω ≧1012 ≧1012 ≧1011 Arc resistance ASTM D495 sec. ≧185 ≧195 ≧195 Tracking index IEC pub112 V ≧900 ≧900 ≧900 Dielectric constant, 1MHz JIS K6911 - 5.5 5.5 4.5 Dissiopation factor, 1MHz JIS K6911 - 0.01 0.01 0.01 Mechanical properties Flexural strength JIS K6911 MPa 70~110 90~120 100~130 modulus JIS K6911 GPa 14~18 12~18 8~16 JIS K6911 % 0.6~1.0 0.8~1.4 1.0~1.4 Tensile strength JIS K6911 MPa 30~50 35~55 40~50 modulus JIS K6911 MPa 600~800 600~900 600~800 Barcol hardness, #934-1 JIS K6911 - ≧60 ≧60 ≧60 Flame retardance UL 94 - - V-0

(0.75mm)V-0

(0.75mm)Physical properties Water absorption, 24hr JIS K6911 % ≦0.05 ≦0.06 ≦0.06 Density JIS K6911 g/cm3 2.15 2.10 2.05 Mold shrinkage JIS K6911 % 0.5~0.7 0.5~0.7 0.5~0.7 Numerical values are representative values, not guaranteed values.

-

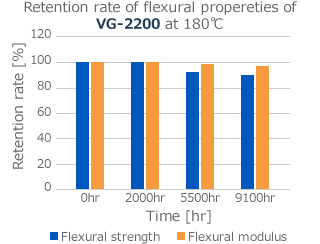

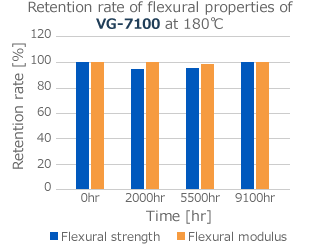

Thermal Degradation ResistanceVyloglass has excellent thermal resistance.Vyloglass retains its excellent mechanical properties even after being subjected to thermal degradation tests (180 ℃, air).

Retention Rate of Flexural Strength of Vyloglass

Retention Rate of Flexural Strength of Vyloglass Retention Rate of Flexural Modulus of Vyloglass

Retention Rate of Flexural Modulus of Vyloglass -

Heat Cycling ResistanceVyloglass has excellent heat cycling resistance.Vyloglass retains its excellent mechanical properties even under extreme temperature changes.Heat Cycling Test -1

20 cycles, where -13 ℃×2 hr → r.t.×2 hr → 200 ℃×2 hrProperties Before After Flexural Strength [MPa] 104 104 Tensile Strength [MPa] 55 57 Change of properties of VG-2200 in test 1Properties Before After Flexural Strength [MPa] 101 114 Tensile Strength [MPa] 53 56 Change of properties of VG-7100 in test 1Heat Cycling Test -2

20 cycles, where -13 ℃×3 hr → r.t.×3 hr → (65 ℃ +100%RH)×3 hrProperties Before After Flexural Strength [MPa] 104 104 Tensile Strength [MPa] 55 57 Change of properties of VG-2200 in test 2Properties Before After Flexural Strength [MPa] 101 114 Tensile Strength [MPa] 53 56 Change of properties of VG-7100 in test 2 -

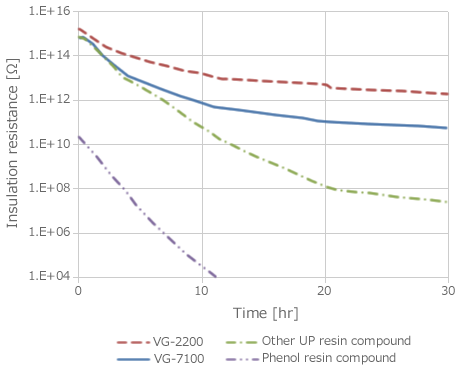

Insulation ResistanceVyloglass has excellent insulation resistance.Unlike phenol resin compounds and other unsaturated polyester (UP) resin compounds, which are used in conventional electrical components, Vyloglass maintains its high insulation resistance even when boiled.

-

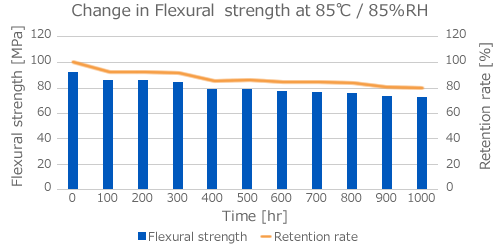

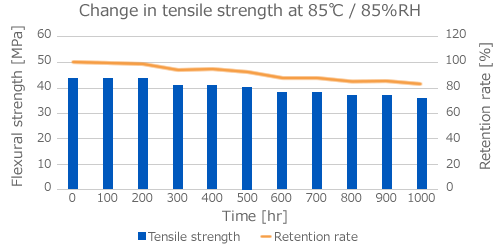

Thermal & Moisture Degradation ResistanceVyloglass has excellent thermal and moisture resistance.Vyloglass maintains its excellent mechanical properties even after being subjected to environmental tests.

Retention Rate of Flexural Strength of VG-7100

Retention Rate of Flexural Strength of VG-7100 Retention Rate of Tensile Modulus of VG-7100

Retention Rate of Tensile Modulus of VG-7100 -

Oil ResistanceVyloglass has excellent oil resistance.Vyloglass is suitable for electronic devices and electrical components of automobiles.Engine Oil (10W-50)120℃ × 200days

Properties VG-2200 VG-7100 Surface Condition [MPa] good good Retention Rate

of Flexural Strength[%] 100 100 Change of properties of Vyloglass in Engine Oil150℃ × 100daysProperties VG-2200 VG-7100 Surface Condition [MPa] good good Retention Rate

of Flexural Strength[%] 100 100 Change of properties of Vyloglass in Engine OilTransmission Oil (GL-4)120℃ × 200daysProperties VG-2200 VG-7100 Surface Condition [MPa] good good Retention Rate

of Flexural Strength[%] 100 100 Change of properties of Vyloglass in Transmission Oil150℃ × 100daysProperties VG-2200 VG-7100 Surface Condition [MPa] good good Retention Rate

of Flexural Strength[%] 100 100 Change of properties of Vyloglass in Transmission Oil -

Flame RetardanceVyloglass is a halogen and antimony-free compound.

Material Limiting Oxygen Index UL94 Grade VG-2200 33% - VG-7100 70% V-0 PE 18% HB PBT 21% HB PC 24% V-2 PEEK 43% V-0 PPS 46% V-0 Limiting oxygen index : the minimum concentration of oxygen required to initiate the combustion of a polymer UL94 Grade : V-0 > V-1 > V-2 > HB -

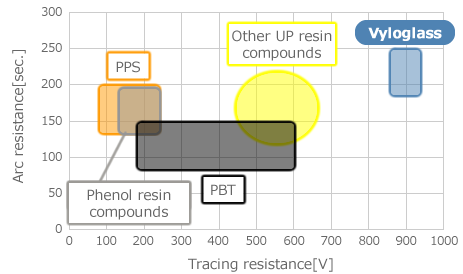

Tracking & Arc ResistanceVyloglass has excellent tracking and arc resistance.Products made up of Vyloglass are highly safe in high voltage environments and under continuous environments.

-

Applications

Terminal block of drainage pump

Terminal block of drainage pump

Press molding

<insulation resistance> Light socket

Light socket

Injection molding

<tracking resistance, insulation resistance> Ignition plug holder

Ignition plug holder

Injection molding

<high dielectric strength, insulation resistance, arc resistance, heat resistance> Parts of electrical generator

Parts of electrical generator

Injection molding

<heat resistance, tracking resistance>